Produce functional parts that require high stiffness with a good surface finish and high impact resistance. Attributes are similar to Polypropylene (PP). This material is impact-resistant and is ideal for tooling applications, manufacturing aids, brackets, jigs and fixtures, housings and consumer applications, such as insoles.

Tough, high-temperature material. Ideal for molds and end-use parts with up to 80°C operating temperature. Excellent surface finish and dimensional accuracy. Also suitable for interior automotive components and other applications requiring high modulus properties.

KeyGuide is a dental 3d printing material, ideal for fabricating transparent surgical guides, allowing doctors to place implants at precise angle & depth.

Single component industrial strength UV resin that cures to a soft (47A), elastomeric material. Suitable for applications where resilience, snap back, and tear resistance is desired, such as lattice structures and functional prototyping.

LOCTITE® 3D MED 413 by Henkel is ideal for use in a wide variety medical devices & applications: durable & reusable medical components, orthotics and more.

Light-curing resin for the production of denture bases. The material provides for accurate results with an outstanding dimensional stability. FotoDent® denture is MMA-free and stable of colour.

P3™ Stretch™ 80은 DLP용 범용 고속 프린트 엘라스토머로 기존 폴리우레탄이나 TPU를 훌륭하게 대체합니다. 더 알아보기

Reactive urethane photopolymer for tough applications that require a combination of high strength, long-term toughness and impact resistance.

Single component elastomer with high resilience and rebound. Capable of maintaining excellent tensile strength and does not require thermal post-processing. It is comparable to commercial TPUs, with a Shore A hardness of 75. Ideal for lattice structures; e.g., mid-soles and soft inserts.

매끄러운 표면 마감을 제공하는 내고온성 수지. 소비재, 자동차 산업과 기타 분야에 이상적인 선택입니다. 지금 자세히 알아보세요.

Somos® WeatherX 100은 기능성 최종 사용 부품을 3D 프린팅하기 위해 개발된 친환경 DLP 포토폴리머입니다. 여기에서 샘플을 받으세요>

Ultracur3D® RG 3280 by Forward AM is a highly loaded, ceramic-filled material with extremely high stiffness around 10 GPa and a Heat Deflection Temperature above 280°C. The white, ceramic-like colored resin is very easy to handle and print, especially considering the high particle loading.

KeyPrint® KeyDenture Try-In™ takes the uncertainty out of the denture fifitting process. Designed for precision and effifficiency, KeyDenture Try-In is a photopolymer resin indicated for 3D printing of biocompatible, short-term trial dentures, intended for evaluation of fifit, occlusion, esthetics, and phonetics during try-in appointments.

The Biocompatible Origin One DM200 is a universal resin, suitable for multiple applications including dental models, surgical guides, denture try-ins, and custom trays.

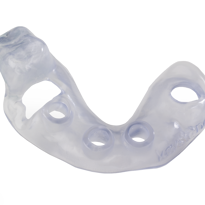

KeySplint Hard is designed for rigid dental splints. KeySplint Hard provides therapy for bruxism and cases where tooth immobilization is needed.

High-performance, high-modulus product with excellent flexural and tensile physical properties and outstanding flame retardance. Suitable for aerospace and transportation components that require flame resistance, high HDT or chemical resistance. Ideal applications include HVAC components, clips and plugs for control systems, connectors, clamps, ducts, brackets.

Our first photopolymer from Evonik is a strong, heat-resistant material that addresses applications where a combination of high-temperature resistance and good elongation at break are crucial. P3 Deflect 120 has low viscosity and high green strength, which make it suitable for parts with challenging geometries such as wiring housings, connectors, or mold tooling.

KeyCast’s low shrinkage formula controls thermal expansion to yield porous-free and accurate castings. KeyCast is compatible with rapid burnout and gradual temperature ramp workflows, with no residual ash. It is used with chrome, cobalt, gold, and silver.

Strong and flexible, ideal for printing splints, night guards and bleaching trays.

KeyTray is a strong, biocompatible (Class I) 3D printing resin designed to create customized, individual impression trays quickly and with precision. The material is strong and durable to withstand the forces of taking a patient impression and removing the tray from the oral cavity. It is compatible with all types of impression material.